UTIFLEX 宇航级超轻电缆组件

发布时间:2025-11-5 9:25:5

加入购物车

Micro-Coax为轨道及轨道外宇航级应用提供高可靠性产品,有超过三十年的经验。我们的广泛的提供微波传输线记录产品提供了最苛刻的任务保证航天技术挑战。我们最受欢迎的产品线为航天电缆组件,由KEVLAR®开始,基于金属化纤维称为ARACON®。 这种超轻型材料,最初由杜邦公司发明的,现在由Micro-Coax改进,为节省重量提供了巨大的机会并没有浪费时间在传统的同轴电缆性能的材料。 轻同轴电缆损耗最低的每克的质量的一个关键组成部分减少发射成本或为许多客户增加卫星有效载荷能力。 我们全部的射频空间合格产品组合包括UTiFLEX® Microwave Flexible Cable Assemblies,high power multipactor resistant TNC connectors、Semi Rigid Cable and Cable Assemblies,以及Spline Cables。 Micro-Coax能力和经验让我们的客户,以确保他们每一个可靠和负担得起的解决方案,,都达到最低的项目风险。

Micro-Coax宇航级组件的其他优点包括:

高可靠性

Micro-Coax solutions are proven highly reliable. Extensive acceptance testing exceeds industry standards from the connector and cable component level through to the final delivered product. Additionally, qualification testing focused on the unique requirements of space flight performed in our own laboratories ensures that all products will perform as specified from integration, launch, through to the end of program life and beyond.

超低重量

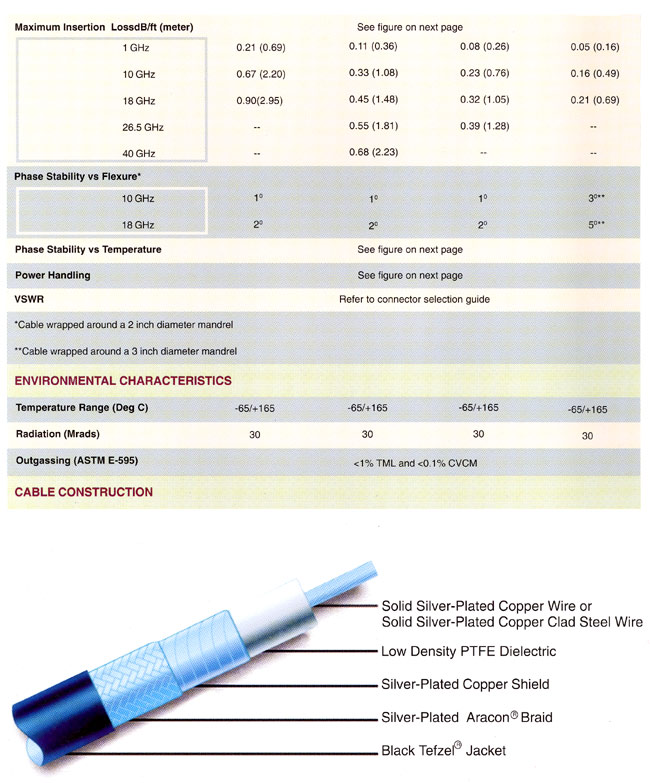

Micro-Coax offers cable constructions built with ARACON® Metal Clad Fiber. Our ultra light cable constructions can weigh up to 35% less than conventional assemblies with no sacrifice in electrical or mechanical performance. ARACON is the only composite shielding fiber based on KEVLAR® from DuPont with more spaceflight heritage than any other lightweight fiber.由ARACON金属化纤维材料组成,在相同电气与结构性能参数的情况下,比常规线缆降低至少35%的重量。

NASA AND J-STD-001ES CERTIFIED NASA以及美军标认证

Micro-Coax assemblers are trained and certified to complete hand soldering operations in accordance with NASA-STD-8739.3 and J-STD-001ES.

宇航级组件制程:

-

Burr-free connector components verified at 30x magnification minimum

-

Connector component plating quality controls exceeding industry standards

-

Proprietary degolding processes meeting the requirements of NASA-STD-8739.3 and J-STD-001ES

-

Thermal stabilization of components prior to assembly

-

Class 10,000 clean room environment for the construction of spaceflight connectors and cable assemblies.

-

Real-time x-ray to ensure proper connector to cable assembly and solder fill and workmanship to the stringent requirements of the space customer

-

100% inspection of all electrical and mechanical requirements

-

Hand cleaning of all assemblies to include connector interfaces prior to packaging

-

ESD safe packaging purged and backfilled with nitrogen before being heat-sealed

MULTIPACTION RESISTANT CONNECTOR DESIGNS微电抗连接器设计

-

Many custom and standard connector designs are available for multipaction sensitive applications

-

Custom connector designs for multipaction applications are designed in accordance with NASA and ESA recommendations 按照NASA与ESA推荐进行设计

RADIATION RESISTANCE 抗辐照能力

-

UTiFLEX cable assemblies for spaceflight applications are offered with FEP and Tefzel® jackets.

-

Standard UTiFLEX FEP jacketed cable designs are proven to resist up to more than 30 Mrads of radiation and Tefzel jacketed designs up to 100 Mrads 标准的UtiFLEX FEP套线可达到30Mrads的抗辐照水平,而Tefzel套线可达100Mrads

MINIMIZED PASSIVE INTERMODULATION INTERFERENCE 最小的PIM无源互调

Cable & connector materials and finishes are carefully selected to minimize effects due to passive intermodulation

优异的热稳定性

-

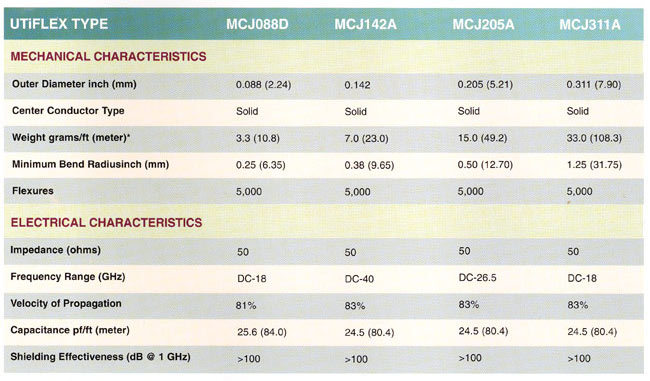

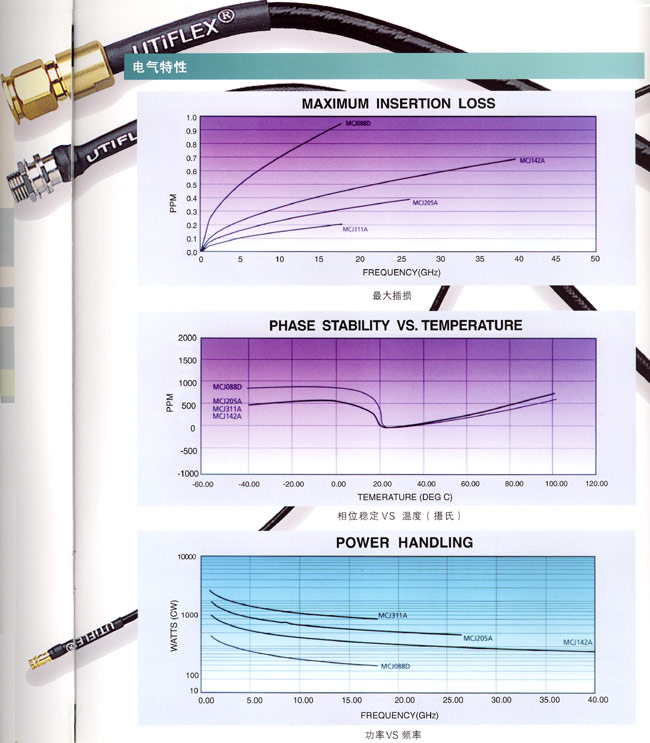

Micro-Coax offers a wide selection of cables which optimize loss and phase stability versus temperature along with excellent mechanical stability over a wide range of thermal extremes

NON-OUTGASSING MATERIALS非真空逸气材料

Micro-Coax spaceflight cable assemblies are manufactured with parts and materials with a maximum Total Mass Loss (TML) of 1% or Collectible Volatile Condensable Material Level of 0.1% when tested per ASTM E-595